Ever sit in your car and feel the seat wobble when you lean back? Or worse - try to slide it forward and it just sticks halfway? It’s not just annoying. A loose or broken seat track can be dangerous, especially during sudden stops or turns. These systems are meant to hold you firmly in place, not shift under pressure. The good news? Most seat track and mechanism problems can be fixed without replacing the whole seat. You don’t need a dealership quote to fix this.

How Seat Tracks Work - Simple Breakdown

Every car seat has two main parts: the track and the mechanism. The track is the metal rail bolted to the floor. The mechanism is what moves the seat along that rail. There are two types: manual and power.

Manual seats use a d-shaped pin that clicks into teeth along the track. Pull the handle, the pin disengages, and you slide. Let go, and it locks back in. Simple. Reliable. But over time, those teeth wear down, or the pin gets bent. Then the seat won’t stay put.

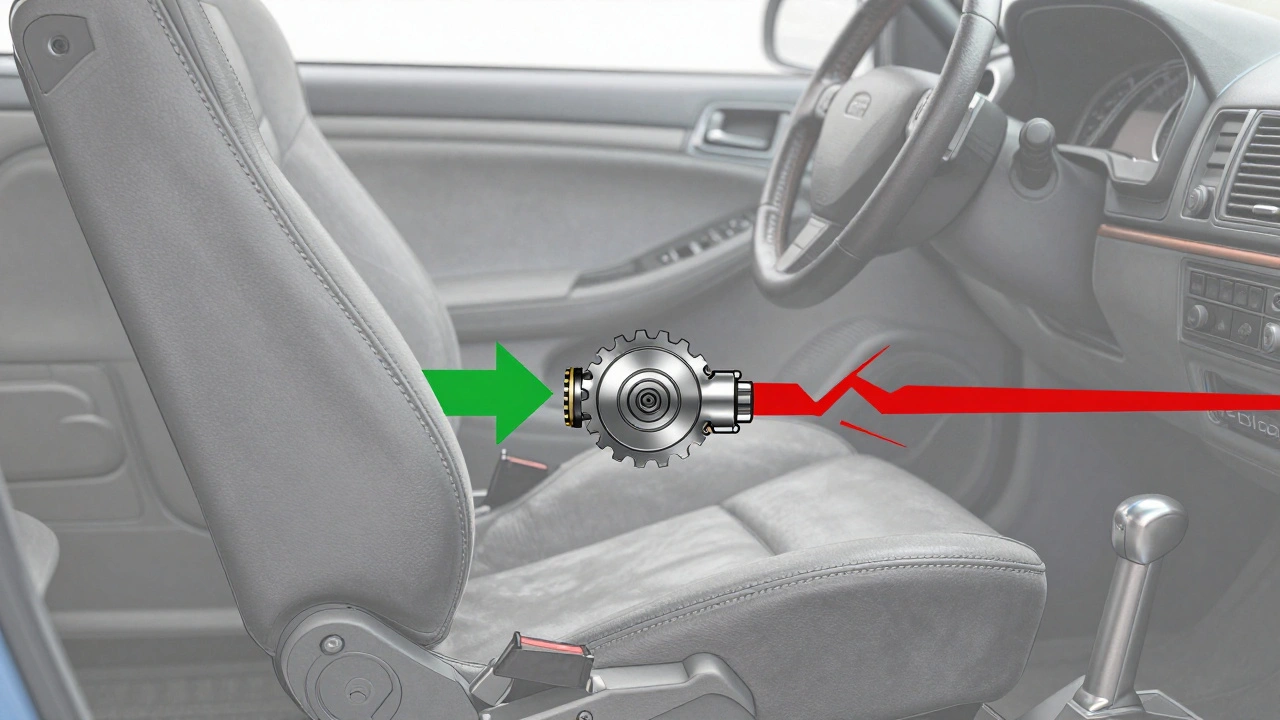

Power seats add a motor, gears, and a drive shaft. When you press the button, electricity turns a small motor. That motor spins a worm gear, which pushes the seat forward or back. Reclining works the same way - a second motor and gear set tilts the backrest. But here’s the catch: these systems are full of plastic and rubber parts that dry out, crack, or break after 10-15 years. Lubrication dries up. Connectors corrode. Gears strip. And suddenly, your seat won’t move at all.

Why Your Seat Slides or Won’t Recline

Most seat issues come down to three things: wear, lack of lubrication, or electrical failure.

- Worn teeth on the track? The d-pin slips. You can slide the seat with your hand - that’s bad.

- Broken gear blocks? In power seats, the plastic gear assembly that connects the motor to the track often cracks. That’s common in 1990s Fords and early 2000s GMs.

- Corroded connectors? If the seat moves half a inch and stops, check the wiring under the carpet. Moisture from spills or leaks eats away at the metal pins inside the plug.

- Loose worm gear? In GM vehicles, if the silver block inside the worm gear assembly isn’t centered, the left and right sides move out of sync. One side slides, the other doesn’t. That’s a safety hazard.

It’s not random. These problems show up in older cars because the materials used in the 90s and early 2000s weren’t built to last 20+ years. Plastic gears get brittle. Rubber boots crack. Electrical grease turns into crust. And once lubrication fails, metal grinds on metal - and that’s when things break for good.

Fixing a Manual Seat: The D-Pin and Track

For manual seats, start by sliding the seat all the way forward and backward. You’ll find bolts under the front and rear of each rail. Remove them. Lift the seat out - you’ll need to disconnect the seatbelt anchor if it’s attached to the frame.

Now, look at the track. Run your finger along the teeth. Are they smooth? Sharp? If they’re rounded, the pin won’t grip. That’s your problem. You can’t replace just the teeth. You need a new track.

Check the d-pin. Is it bent? Cracked? If so, replace it. Most auto parts stores sell replacement pins for common models. Make sure the new one matches the old one exactly. Install it, slide the seat back, and test. It should click into every position without slipping. If it still moves, the track is worn out. Time for a replacement.

Fixing a Power Seat: Step-by-Step

Power seats are more complex. But they’re fixable. Here’s how to tackle the most common issues.

Step 1: Disconnect the Battery

Always start here. Airbag systems are wired through the seat. A spark could trigger them. Remove the negative terminal. Wait 10 minutes.

Step 2: Remove the Seat

Unbolt the four main bolts (usually 15mm) under the seat. Slide the seat forward to access the rear bolts. Unplug the main electrical connector under the seat. It’s usually a large gray or black plug with a red locking tab. Use a flathead screwdriver to gently pry the tab open before pulling it out.

Step 3: Inspect the Track and Motor

Flip the seat upside down. Look at the gear assembly. If you see cracks in the plastic housing, that’s your issue. For Ford Mustangs (1992-1998), the forward-back motor’s gear block is notorious for breaking. You’ll need a repair kit - like the LRS-14547RK from Late Model Restoration. It includes new gear blocks, slide pins, and cotter pins.

Remove the four 10mm bolts holding the track to the seat. Then remove the two Torx screws holding the motor. Pull the flexible drive shaft off both ends. Mark the motor wires - red is positive, black is negative. Use a marker or tape. Don’t mix them up.

Step 4: Replace the Gear Assembly

On the passenger side, remove the T45 Torx bolt holding the gear screw block. Drill out the factory slide pin with a 3/8-inch bit. Tap it out with a hammer and drift. Discard it. Install the new pin from the kit. Slide the new gear assembly into place. Make sure the plastic retainer and drive shaft boot stay intact - you’ll reuse them.

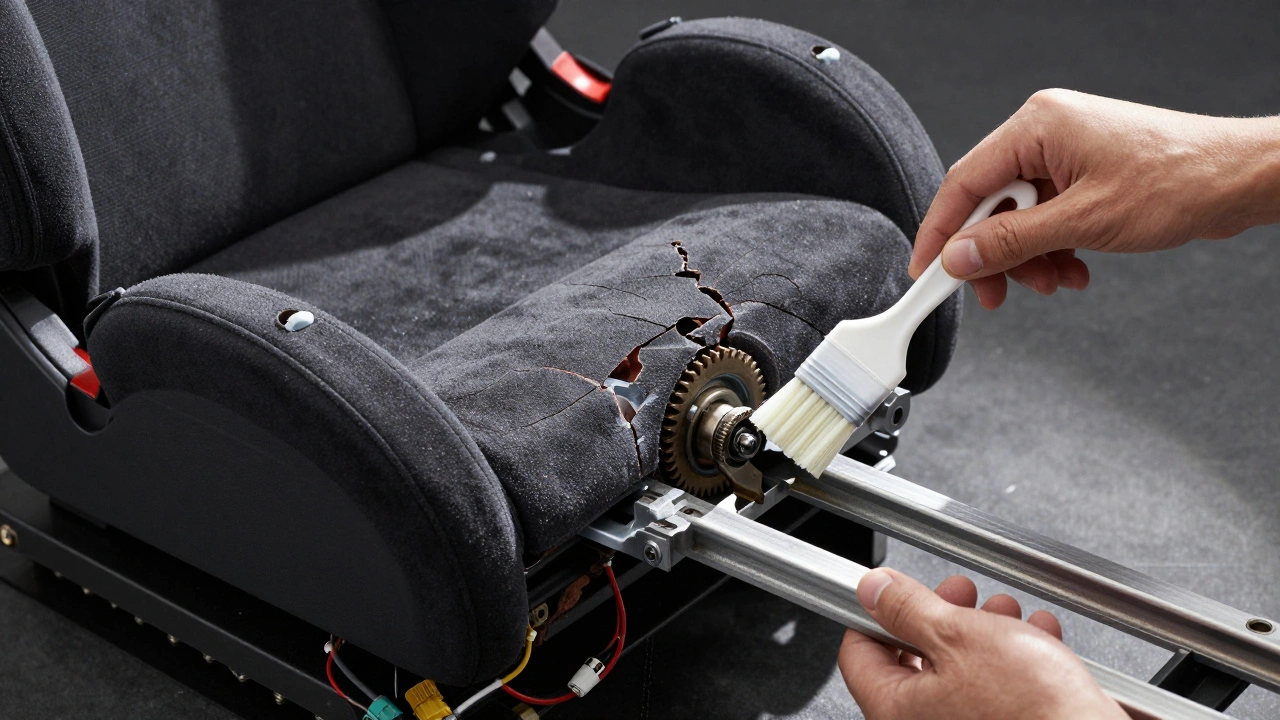

Step 5: Lubricate

This is where most repairs fail. You can’t just bolt it back together. Use white lithium grease on all gears and the metal rails. Don’t use WD-40 here - it’s a cleaner, not a lubricant. It’ll dry out fast. Apply the grease evenly. Then use WD-40 on the slider rails to loosen any built-up grime. Move the track back and forth by hand until it slides smoothly.

Step 6: Reinstall the Motor

Count how many times the motor turns when you remove it. Then turn it back the same number of times when reinstalling. This keeps the calibration right. If you don’t, the seat might move too far or not far enough. Reconnect the drive shaft. Plug the motor back in. Test it before bolting the seat down.

GM Power Seats: The Worm Gear Block Fix

GM, Chevrolet, and GMC vehicles have a different failure point: the worm gear block. It’s the silver metal piece that holds the black follower block inside. Over time, the block shifts forward, and the left and right rails fall out of sync.

Remove the seat. Find the inspection holes on the side of the track. Look through them. If the black block is pushed all the way forward, that’s your problem.

Remove the E10 and E12 Torx bolts holding the worm gear. Use a 15mm wrench to hold the nut on the other side. Pull the worm gear out. Install the shims from a GM repair kit (like those from gmcatrep.com). The angled side of the black block must face UP. Slide the worm gear back in. Turn it until the black block is fully forward. Then turn it back just a little - about 1/8 turn. That’s the sweet spot for synchronization.

Reinstall the drive shaft. Press down gently to seat it. Apply thread locker to the bolt. Reconnect the motor. Test the seat while it’s still upside down. If both sides move together - you fixed it.

What to Avoid

- Don’t force the seat. If it won’t move, don’t yank it. That breaks gears.

- Don’t use engine oil or motor oil to lubricate. It attracts dust and gunk.

- Don’t skip the battery disconnect. You risk airbag deployment.

- Don’t reuse old slide pins or cotter pins. They’re cheap. Replace them.

- Don’t ignore the electrical connector. Clean the pins with contact cleaner if they’re green or crusty.

When to Replace Instead of Repair

Some seats are beyond repair. If the track is bent, cracked, or rusted through, don’t try to fix it. It’s a safety risk. Same if the motor is dead and the gear housing is shattered. Replacement seats from salvage yards cost less than $100 on many models. And they come with working tracks and motors.

But for most cars - especially Fords from the 90s and GMs from the 2000s - repair kits exist. They’re affordable. They work. And they’ll get you another 5-10 years out of your seat.

Prevention: Keep Your Seats Working

Every 2 years, pull your seat forward and back 5-10 times. That keeps the gears moving. Spray a little white lithium grease on the track rails. Wipe off excess. Do the same for the recline mechanism if it’s manual.

Keep spills off the seat. Moisture gets under the carpet and into the connectors. If you have kids or pets, use seat covers. It’s cheap insurance.

And if you hear grinding? Don’t wait. Fix it before the gear strips. A $20 repair kit today saves you a $600 dealership bill tomorrow.